A Furnace for Firing Ceramic Products Is Called

Firing also called sintering involves heating the raw ceramic to a temperature below the melting point. Incise to remove or subtract clay by cutting into the surface.

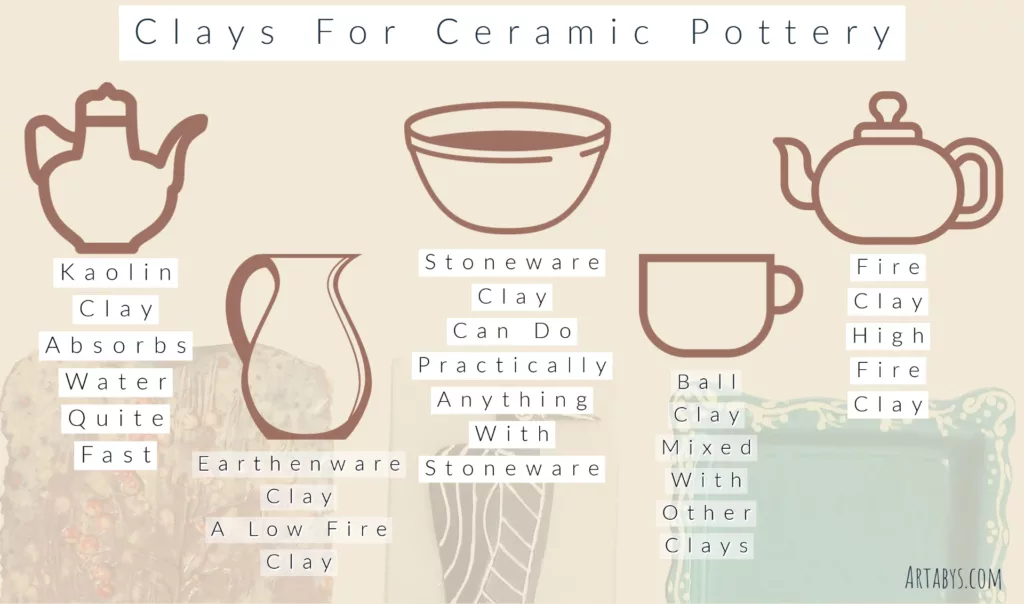

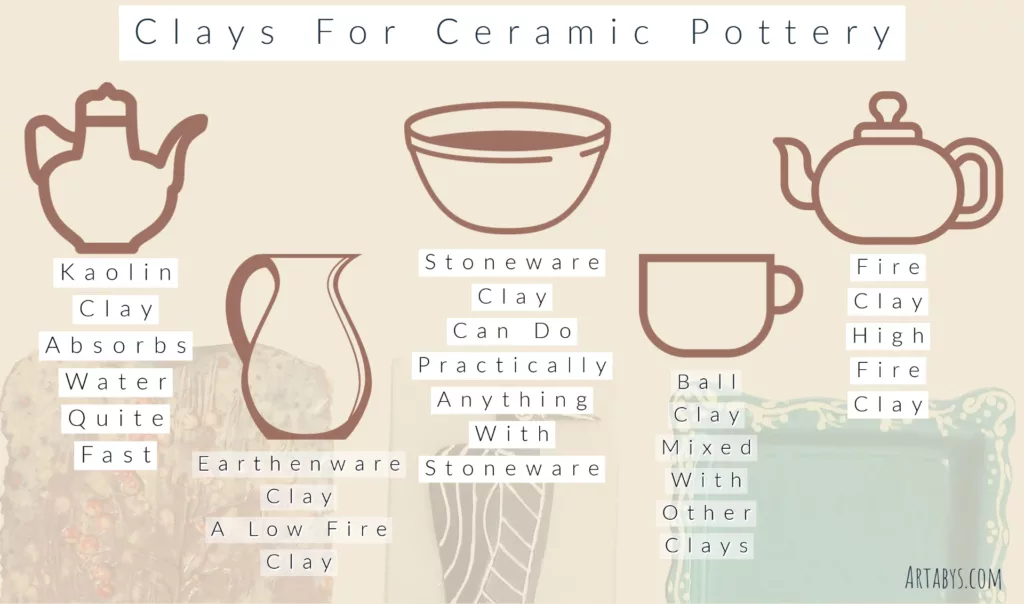

What Clay Do You Need For Ceramic Pottery Artabys

Examples are stamping and rouletting.

. Kiln technology is quite ancient. 3311 Flat flame burner. Ceramics are tough and strong and similar in some ways to stone.

1 the art and wares made by potters. Request PDF Design and implementation of an electrical furnace for firing ceramic products In this study an electrical furnace for firing the ceramic products which its heat reaches up to. Engraving a decoration into unfired clay.

Fired object Transmission electron micrograph. At least one of the plurality of heat generation bodies includes a plurality of resistance heater elements. ONEJOON has successfully built pusher slab furnaces for almost all industries and products.

2 a ceramic material 3 a place where pottery wares are made. At 1832F 1000C the clay crystals begin to break down and melt. Kneading is a step in preparing clay for shaping.

Maximum furnace length over 40 m. 15 shows a typical staged-fuel flat flame gas burner. The ring-like base of a ceramic piece usually heavier than the surrounding body glaze firing a firing cycle to the temp at which the glaze materials will melt to form a glass-like coating greenware pottery which has not been bisque fired kiln a furnace made of refractory clay materials for firing ceramic products leather hard.

A furnace or fired heater. Kiln A furnace for firing ceramic products. The car is moved to a position outside the furnace for loading and unloading.

Each heating element is formed of a material containing irregularly oriented crystal grains. A similar principle is applied in the so-called Elevator Furnaces. Lip The rim of the openings or mouth of a vessel Leather Hard The condition of raw clay ware when most of the moisture has evaporated leaving it still soft enough.

See answer 1 Best Answer. Also called a furnace in American English when used for heating and hot water in a building. Why ONEJOON is the leader in pusher Slab Furnace technology.

Aggressive special or standard atmospheres. One recent application is one in which a series of discs is formed from a ceramic powder mixed into a slurry and pressed in a 20-ton press to various sizes. Enameling furnaces Curing or firing a porcelain vitreous enameling coating is done in high temperature enameling furnaces.

Transfer heat generated by the combustion of natural gas ethane propane or fuel oil. And 4 the business of the potter. In the early days these enameling furnaces were made of refractory bricks due to the required firing temperature between 800 and 850 degrees Celsius.

A firing furnace having a structure which prolongs the durability of an insulative member includes a plurality of heat generation bodies arranged in the housing for generating heat with power supplied from an external power supply a connection member for connecting the external power supply and the heat generation bodies a fixing member attached to the housing and. A furnace for the firing of ceramics. The firing furnace includes a housing including a firing chamber and a plurality of heat generation bodies arranged in the housing and generating heat with power supplied from a power supply to heat the firing subject in the firing chamber.

High-temperature furnaces are used to fire ceramics found in many of these electronic fields. Kiln spurs Supports often in the shape of a tripod used to maintain the shape and separate pieces of ceramic during the firing process. When mullite forms from metakaolin Al2O32SiO2 extra free silica is released.

Consist essentially of a battery of pipes or tubes that run along the sides and roof of the firebox. Ad Manufacturing Ceramic Parts Components to Customer Prints. At 1922F 1050C needle shaped crystals of mullite 3Al2O32SiO2 begin to form giving the fired clay strength and hardness.

Pieces of pottery have survived for thousands of years all because clay met fire. A firing furnace includes a housing having a firing chamber for receiving a firing subject and a plurality of heating elements for generating heat when supplied with current to heat the firing subject in the firing chamber. Some applications including some reformer and cracking furnace designs require a flat or fan-shaped flame due to the close proximity of process tubes or due to the fact that the burner is fired along a wall or across the floor.

High-temperature sintering up to over 2000 C. A method of decoration in which an object is pressed into the clay in order to create a design or image in the surface. The temperature needed to transform soft clay into hard ceramic is extremely.

A firing furnace for firing a firing subject. A device used to heat up chemicals or chemical mixtures. Firing clay transforms it from its humble soft beginnings into a new durable substance.

Exceptions are those used for technical structural or refractory applications. This eliminates the moisture and binder shrinking the microscopic gaps between particles and fusing them together to form fine ceramic products of extreme hardness and density. Jetstream furnace or Tempest boiler a design of wood-fired water heater.

Use of ceramic and metallic muffles. KILNS AND FURNACES USED IN CERAMIC AND REFRACTORY INDUSTRIES KILNS AND FURNACES USED IN CERAMIC AND REFRACTORY INDUSTRIES A General Description And Comparison Fig - Tunnel Kiln Car loaded with Wares Refractory Bricks coming out of the Kiln after Firing. Kiln An electric or gas furnace for firing ceramic products.

The fired clay is known as metakaolin. All fired ceramic wares of materials which when shaped contain a significant amount of clay. What is a furnace for firing clay pottery called.

The Reverberatory type Coal Fired Grate Furnaces have bridge wall over which the flame sweeps into the furnace hearth. Expert Customer Service in Aerospace Industrial Ceramic Machining and Grinding. Boiler used to heat water.

This type of furnace is generally used for firing heavy or bulky shaped bricks. Kiln furniture devices and implements inside furnaces used during the heating of manufactures individual pieces such as pottery. Each heating element is manufactured by applying pressure entirely to.

A furnace in American English or a heater or boiler in British English used to generate heat for buildings. Brett Worth EyeEm.

Factors To Consider In Ceramic Drying And Firing 2017 08 01 Industrial Heating

Pottery Drying Turning And Firing Britannica

0 Response to "A Furnace for Firing Ceramic Products Is Called"

Post a Comment